The Finished Mark

Permanence

The word permanence can be open to interpretation, with many claimed “permanent” marks being easily removed by chemicals or degrading over time. Because the CerMark material thermally bonds the glass frit and inorganic pigments it brings an unparalleled level of permanence to laser marking. This includes resistance to chemicals such as acids and bases, UV exposure, abrasion and extreme temperature.

The word permanence can be open to interpretation, with many claimed “permanent” marks being easily removed by chemicals or degrading over time. Because the CerMark material thermally bonds the glass frit and inorganic pigments it brings an unparalleled level of permanence to laser marking. This includes resistance to chemicals such as acids and bases, UV exposure, abrasion and extreme temperature.

Contrast & Resolution

Whether you are looking for improved machine readability on barcodes, clear instructions or instant brand recognition on a decorative panel, CerMark laser marking materials offer a strong benefit. The laser bonding process delivers high resolution with variable data while the mark color provides a contrast with the substrate which may be missing with a direct mark. Improvements in contrast can lead to tangible cost savings in a manufacturing environment.

Whether you are looking for improved machine readability on barcodes, clear instructions or instant brand recognition on a decorative panel, CerMark laser marking materials offer a strong benefit. The laser bonding process delivers high resolution with variable data while the mark color provides a contrast with the substrate which may be missing with a direct mark. Improvements in contrast can lead to tangible cost savings in a manufacturing environment.

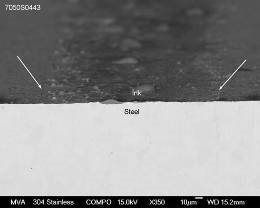

Effect on the Substrate

One of the main advantages of the CerMark laser marking process is it has a minimal effect on the integrity of the substrate being marked. Other direct marking solutions such as dot-peening and engraving physically indent or remove the surface making them unsuitable for plated or hard surfaces. Direct laser marks either ablate or anneal the substrate material which can lead to corrosion or structural change in the material. CerMark laser marking materials use less thermal energy to create a surface bond, preserving the substrate integrity and making them suitable for critical or difficult applications such as aerospace or industrial ceramics.

One of the main advantages of the CerMark laser marking process is it has a minimal effect on the integrity of the substrate being marked. Other direct marking solutions such as dot-peening and engraving physically indent or remove the surface making them unsuitable for plated or hard surfaces. Direct laser marks either ablate or anneal the substrate material which can lead to corrosion or structural change in the material. CerMark laser marking materials use less thermal energy to create a surface bond, preserving the substrate integrity and making them suitable for critical or difficult applications such as aerospace or industrial ceramics.

Cycle Time

There are a larger number of factors which impact the amount of time it will take to make your mark. In many instances, the addition of a CerMark laser marking material will decrease your marking time.